close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

DESCRIPTION

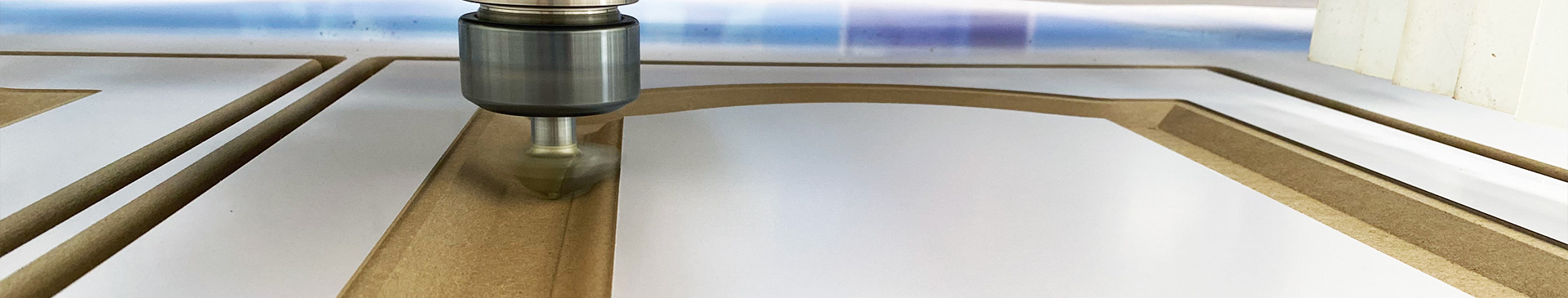

NA-2821F CNC Machine Center automatically loads a 4x8 feet or 2800*2100mm sheet from a pallet by way of a scissor lift located at the rear of the CNC machine. A movable gantry system equipped with suction cups using retractable guide rails and stops on the table safely and accurately guides the material sheet onto the CNC platform. Once the sheet is placed, the vacuum hold down automatically and operator starts the cut cycle for the CNC to execute. After the sheet is fully processed, it is then pushed off to a conveyor table at the front end while another sheet is simultaneously loaded from the rear of the machine again. During this whole process the residual dust or chips that are not picked up from the dust collector are swept off the table and conveyor into various chutes keeping the work cell clear of dust and debris. Upon completion, the individual parts are labeled by the operator through an integrated bar code system. This facilitates clear identification of the finished parts for quick and easy assembly later on.

FEATURES

12HP CC 9.0kw spindle ,ISO30

With loading scissor lift table and unloading conveyor belt

Maintenance free servo motor and driver

12-position LINEAR tool magazine

Double-layer cnc nesting vacuum table

New dust-free design for dust collector hood

Vacuum pump 7.5kw 250m3/h

It works with all industry standard CAD/CAM software

| Series | NA-2821F |

| Working size | 2100*2800*150mm |

| Table size | 2100*2800mm |

| Transmission | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 |

| Travelling speed | 50m/min |

| Working speed | 20m/min |

| Driving system | Inovance |

| Controller | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH |

| Dimension | 1000*2260*2150mm |

DESCRIPTION

NA-2821F CNC Machine Center automatically loads a 4x8 feet or 2800*2100mm sheet from a pallet by way of a scissor lift located at the rear of the CNC machine. A movable gantry system equipped with suction cups using retractable guide rails and stops on the table safely and accurately guides the material sheet onto the CNC platform. Once the sheet is placed, the vacuum hold down automatically and operator starts the cut cycle for the CNC to execute. After the sheet is fully processed, it is then pushed off to a conveyor table at the front end while another sheet is simultaneously loaded from the rear of the machine again. During this whole process the residual dust or chips that are not picked up from the dust collector are swept off the table and conveyor into various chutes keeping the work cell clear of dust and debris. Upon completion, the individual parts are labeled by the operator through an integrated bar code system. This facilitates clear identification of the finished parts for quick and easy assembly later on.

FEATURES

12HP CC 9.0kw spindle ,ISO30

With loading scissor lift table and unloading conveyor belt

Maintenance free servo motor and driver

12-position LINEAR tool magazine

Double-layer cnc nesting vacuum table

New dust-free design for dust collector hood

Vacuum pump 7.5kw 250m3/h

It works with all industry standard CAD/CAM software

| Series | NA-2821F |

| Working size | 2100*2800*150mm |

| Table size | 2100*2800mm |

| Transmission | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 |

| Travelling speed | 50m/min |

| Working speed | 20m/min |

| Driving system | Inovance |

| Controller | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH |

| Dimension | 1000*2260*2150mm |

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com