close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-20 Origin: Site

In the fast-paced world of interior design and modern home furnishings, precision and efficiency have never been more critical. As homeowners and businesses demand personalized aesthetics and streamlined installation, manufacturers must adopt smarter ways to keep up. That's where the CNC nesting machine comes in.

It’s not just about cutting wood. It’s about transforming entire workflows in the furniture industry. In this post, you’ll learn how CNC nesting machines are reshaping furniture production, how they connect to contemporary design needs, and what features matter most when selecting your next machine.

CNC nesting machines are designed for efficient material utilization and precision cutting. These systems use computer-aided design (CAD) and computer-aided manufacturing (CAM) to arrange parts on sheet materials, minimizing waste while maximizing productivity.

Optimized layouts: The software arranges cuts to reduce leftover scraps.

Automated workflows: Loading, cutting, drilling, and unloading can be fully automatic.

Multi-function capabilities: A single machine handles routing, boring, grooving, milling, and engraving.

By automating and integrating these processes, CNC nesting machines streamline everything from cabinet production to complex architectural elements.

CNC nesting machines are essential for furniture makers aiming to deliver precision products quickly and consistently. Here’s how they align with modern design and decor trends:

Flat-pack, modular, and customized storage units are growing in popularity. CNC nesting machines enable:

Seamless production of cabinet bodies, doors, and shelves.

Accurate hinge and dowel hole placement.

Quick iteration for bespoke sizes and finishes.

Contemporary interiors often include unique textures and cutouts. With CNC nesting routers, designers can:

Cut precise geometric wall panels.

Add grooves, recesses, or layered elements.

Work across wood, MDF, acrylic, and more.

Today's furniture includes mixed materials like wood and composite boards. CNC nesting machines can:

Cut complex shapes in layered materials.

Maintain accuracy across diverse densities.

Support seamless joinery for tables, shelves, and storage units.

To make the right investment, furniture manufacturers must assess machines based on performance, flexibility, and future-proofing. Below are core aspects to compare:

| Feature | Description |

|---|---|

| Bed Size | Affects the scale of parts produced; 1300mm x 2500mm is a popular standard. |

| Spindle Power | Determines cutting strength. 9kW air-cooled spindles are ideal for wood. |

| Tool Change System | Automatic tool changers (ATC) increase efficiency during multi-process jobs. |

| Vacuum Table | High-adsorption tables ensure stability of various panel types. |

| Controller | Intuitive systems reduce training time and improve safety. |

| Software Compatibility | Integration with CAD/CAM, nesting, and 3D modeling tools. |

CNC nesting machine technology provides significant competitive advantages, especially for companies focused on speed, quality, and cost-efficiency.

Optimized nesting layouts lead to:

Higher material yields.

Less offcut waste.

Cost-effective production cycles.

Automated workflows reduce manual labor.

Tool changers eliminate setup delays.

Machines operate at high speeds without losing precision.

Repeatable results across thousands of parts.

Ideal for standardized modular furniture components.

Error margin as low as 0.02mm in some machines.

Unlike traditional woodworking systems, CNC nesting routers excel in batch-one manufacturing. This is perfect for businesses responding to:

Client-specific home decor requests.

Personalized wardrobe and cabinet solutions.

Small-run commercial interior orders.

With intuitive design-to-production software, even one-off jobs can be processed efficiently.

Sustainability is now a core expectation across industries. CNC nesting helps manufacturers meet eco-goals through:

Efficient use of raw boards.

Reduced offcuts and waste disposal.

Energy-efficient components.

With CNC nesting machines, companies can create stylish home decor while staying aligned with environmental responsibility.

Implementing CNC nesting into your manufacturing line involves more than just purchasing hardware. Follow these best practices:

Allocate space for sheet loading/unloading.

Plan dust extraction and power routing.

Focus on safety protocols and software use.

Cross-train for tool maintenance and changeovers.

Use tool sensors to reduce manual errors.

Test for precision periodically across X, Y, Z axes.

Keep your nesting software updated for better part arrangement.

Leverage forecasting tools to plan jobs.

Furniture design continues to evolve. CNC nesting must keep pace with industry innovations:

Simulate real-world furniture virtually.

Minimize testing time.

Auto-labeling systems for part traceability.

Ideal for just-in-time (JIT) assembly.

Wood, PVC, aluminum, and more—all processed in one workflow.

Entry-level models designed for workshops.

Portable options with plug-and-play functionality.

| Project Type | How CNC Nesting Helps |

|---|---|

| Kitchen Cabinets | Uniform door fronts, pre-drilled hinges, efficient layout. |

| Bedroom Closets | Custom sizes, internal drawer routing, sliding systems. |

| Wall Panels | Intricate patterns, textured engravings. |

| Office Desks | Cable grooves, edge profiles, ergonomic shaping. |

| Bookshelves | Flush joints, modular shelf slots. |

CNC nesting machines represent a cornerstone of modern furniture manufacturing. Whether you're a custom cabinet maker or a home decor innovator, these machines ensure speed, consistency, and scalability. By adopting the right system and workflow, brands can meet modern design expectations while reducing operational costs.

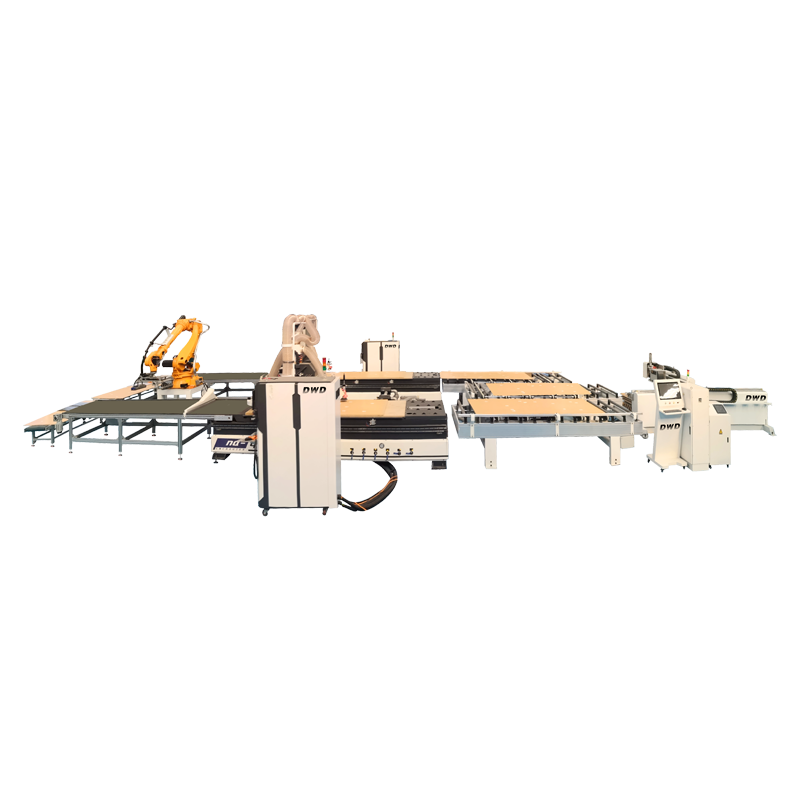

At DWD, we offer CNC nesting machines built specifically for today’s woodworking challenges. Designed with cutting-edge automation and engineered for consistent results, our equipment supports businesses from small workshops to scalable production lines.

A: Most machines are designed for wood-based panels like MDF, plywood, particleboard, as well as certain plastics and soft metals.

A: Absolutely. Many modern machines have compact footprints and easy-to-learn interfaces, making them ideal for custom or low-volume production.

A: Nesting software arranges parts digitally to fit onto panels with minimal gaps, reducing leftover waste and saving costs.

A: Regular cleaning of the vacuum table, spindle checks, and periodic software calibration are essential for optimal performance.

A: Yes, DWD provides lifetime technical support, training guidance, and spare parts services to ensure smooth operations.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com