close

Choose Your Site

Global

Social Media

CNC Router Machine for Furniture Production – High-Precision Woodworking Solution For One Canada Customer

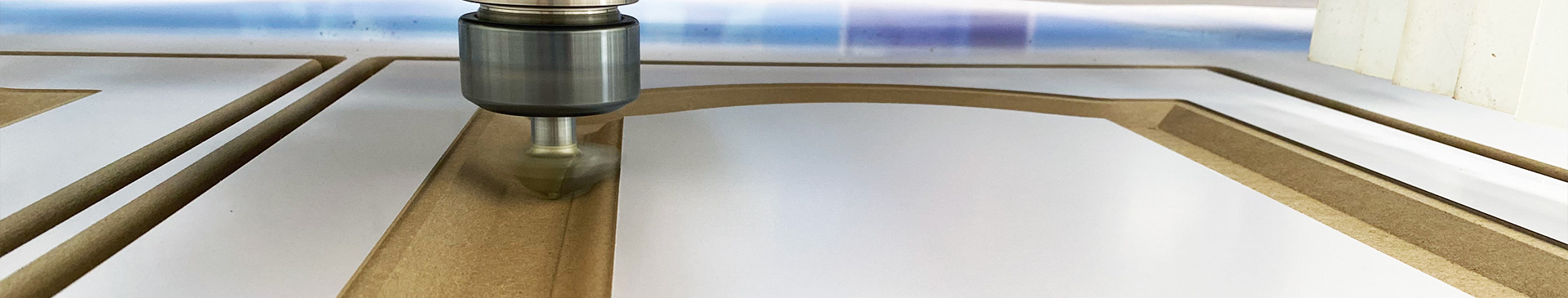

The CNC Router Machine is a high-efficiency, computer-controlled cutting solution designed for modern furniture and cabinet production. Engineered for precision, stability, and continuous operation, this CNC router allows manufacturers to process wood panels with exceptional accuracy while reducing labor and production time. It is ideal for producing wardrobes, kitchen cabinets, office furniture, custom panel furniture, and more.

Key Features

- Automatic label function: One printer was installed beside the gantry, which allows the operator to automatically stick labels on panels before drilling and cutting. This saves a lot of labor and also maintains high accuracy for those panels.

- Automatic Tool Changing : Enables fast switching between tools for drilling, milling, slotting, and engraving.

- multi drillers:Multi-drillers allow manufacturers to drill all holes easily on cabinet panels. Compared with manual drills, these drillers work faster and more accurately.

- Smart Control System: Easy-to-use interface for nesting, contour cutting, and complex furniture designs.

- Germany Becker vacuum pump:Two vacuum pumps work on this table, which will hold the panel flat and tight during cutting.

- automatic loading and unloading table: Designed with automatic loading and unloading, it saves a great deal of the operator's labor and also improves work efficiency.

Technical Specifications

- Working Area: 1600 × 3050 mm

- Spindle Power: 9 kW

- Spindle Speed: 24,000 rpm

- Drive System: Servo motor / rack and pinion

- Table Type: Nesting vacuum table

- Max. Cutting Speed: 25–35 m/min

- Machine Size: 3200 × 2200 × 1800 mm

Applications

Suitable for a wide range of furniture manufacturing tasks, including:

- Cabinet doors and panels

- Wardrobes and closets

- Kitchen cabinet components

- Office furniture

- Custom panel furniture

- Decorative wall panels and partitions

Advantages for Furniture Factories

- Increased production speed compared to manual cutting

- Reduced waste through optimized nesting software

- Consistent, repeatable accuracy for mass production

- Lower labor cost with automated operation

- Smooth edges ready for edge banding and finishing

Cost Considerations

The price of a CNC router varies depending on spindle type, table size, and tool-changing configuration. Manufacturers can choose economical models for small shops or fully automated systems for large-scale furniture factories.

CNC Router Machine for Furniture Production – High-Precision Woodworking Solution For One Canada Customer

The CNC Router Machine is a high-efficiency, computer-controlled cutting solution designed for modern furniture and cabinet production. Engineered for precision, stability, and continuous operation, this CNC router allows manufacturers to process wood panels with exceptional accuracy while reducing labor and production time. It is ideal for producing wardrobes, kitchen cabinets, office furniture, custom panel furniture, and more.

Key Features

- Automatic label function: One printer was installed beside the gantry, which allows the operator to automatically stick labels on panels before drilling and cutting. This saves a lot of labor and also maintains high accuracy for those panels.

- Automatic Tool Changing : Enables fast switching between tools for drilling, milling, slotting, and engraving.

- multi drillers:Multi-drillers allow manufacturers to drill all holes easily on cabinet panels. Compared with manual drills, these drillers work faster and more accurately.

- Smart Control System: Easy-to-use interface for nesting, contour cutting, and complex furniture designs.

- Germany Becker vacuum pump:Two vacuum pumps work on this table, which will hold the panel flat and tight during cutting.

- automatic loading and unloading table: Designed with automatic loading and unloading, it saves a great deal of the operator's labor and also improves work efficiency.

Technical Specifications

- Working Area: 1600 × 3050 mm

- Spindle Power: 9 kW

- Spindle Speed: 24,000 rpm

- Drive System: Servo motor / rack and pinion

- Table Type: Nesting vacuum table

- Max. Cutting Speed: 25–35 m/min

- Machine Size: 3200 × 2200 × 1800 mm

Applications

Suitable for a wide range of furniture manufacturing tasks, including:

- Cabinet doors and panels

- Wardrobes and closets

- Kitchen cabinet components

- Office furniture

- Custom panel furniture

- Decorative wall panels and partitions

Advantages for Furniture Factories

- Increased production speed compared to manual cutting

- Reduced waste through optimized nesting software

- Consistent, repeatable accuracy for mass production

- Lower labor cost with automated operation

- Smooth edges ready for edge banding and finishing

Cost Considerations

The price of a CNC router varies depending on spindle type, table size, and tool-changing configuration. Manufacturers can choose economical models for small shops or fully automated systems for large-scale furniture factories.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com