close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2022-05-27 Origin: Site

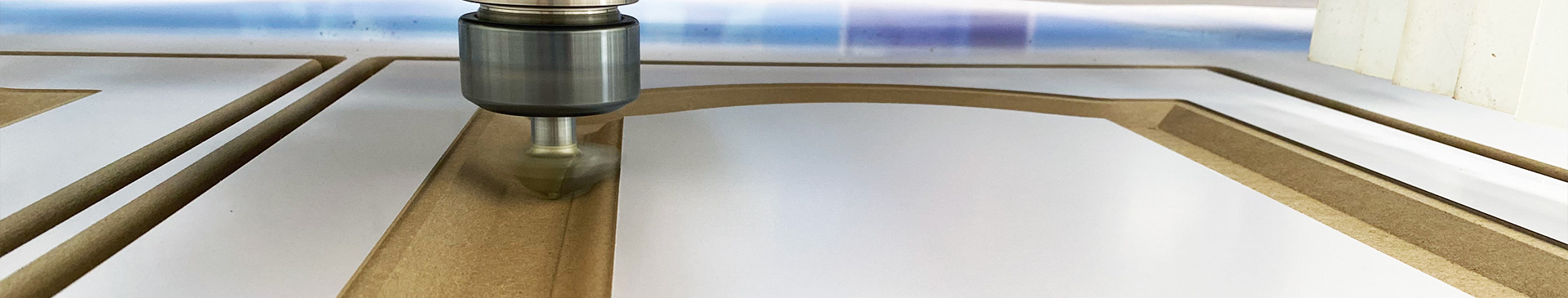

What does CNC machining center mean? How does the nesting center work? What are the advantages of CNC nesting router?

l What does this nesting center mean?

l What are the components of the nesting center?

l What are the advantages of nesting center?

CNC machining refers to machining with CNC tools. CNC indexing control machine using CNC processing language programming control, usually G code. CNC processing G code language tells CNC machine tool processing tool cartesian position coordinates, control tool feed speed and spindle speed, as well as tool change, coolant and other functions. CNC machining has great advantages over manual machining. For example, CNC machining produces parts that are very accurate and repeatable; CNC machining can produce parts with complex shapes that cannot be completed by hand machining. Numerical control machining technology has been widely promoted. Most machining shops have CNC machining capability. The most common CNC processing methods in typical machining workshops are CNC milling, CNC turning.

CNC milling tool called CNC milling machine or CNC machining center. CNC turning lathe is called CNC turning center. G codes for CNC machining can be written manually, but usually machining workshops use CAM (computer aided Manufacturing) software to automatically read CAD (computer aided Design) files and generate G code programs to control CNC machines.

CNC machining center is composed of mechanical equipment and NUMERICAL control system, suitable for processing complex parts of high efficiency automatic machine tools. Comprehensive processing capacity is strong, one clamping can complete more processing content. CNC machining center is suitable for processing shaft parts, CNC machining center is suitable for installing box parts with more complex geometric shapes. Of course, CNC machining centers generally only have two axes and two linkage devices, and CNC machining centers have at least three axes.

CNC machining center is a set of CNC milling machine, CNC boring machine, CNC drilling machine functions in one of the CNC boring and milling machine. It is equipped with a knife library and an automatic tool changer. CNC machining center is a highly automatic multi-functional CNC machine tool, with tool library and automatic tool change device. After the workpiece is clamped once in the machining center, it can complete multiple processes of more than two surfaces, and has a variety of knife change or knife selection functions, which greatly improves the production efficiency.

The main purpose of CNC processing is to remove the excess of raw materials, so that it has the appropriate shape, such as round, rectangular and so on. In traditional methods, these machines are operated by expert operators who operate them. Most jobs require precision machining, and operators should have sufficient expertise to perform precision machining. In CNC machine tools, the role of the operator is minimized. Operators only need to input instructions in the computer program, will be required tools into the machine, other work by the computer automatically completed. The computer according to the operator input instruction program, instruction machine tool for various processing operations.

CNC machining center can process materials including pure metal materials, alloy materials, plastic materials, wood and so on.If you are looking for a CNC nesting router device with good price and quality, DWD MECHATRONICS CO.,LTD is a good choice.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com