close

Choose Your Site

Global

Social Media

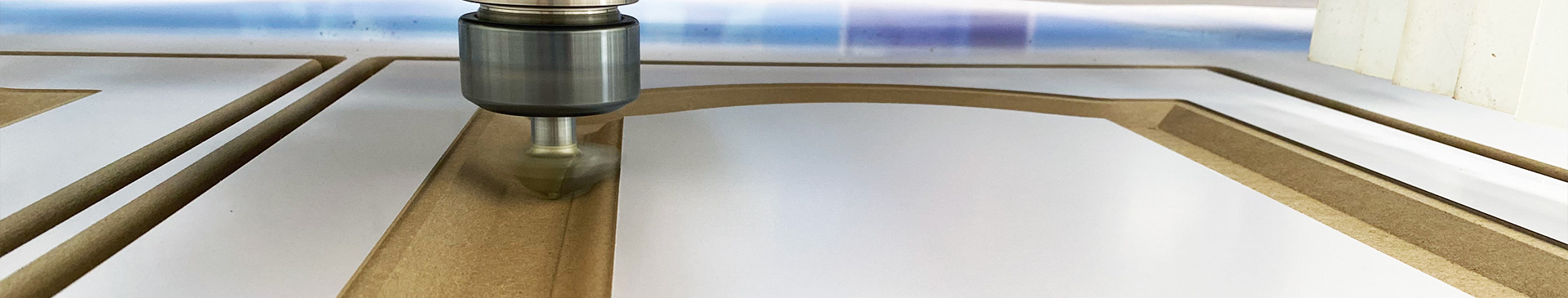

CNC router machine allows manufacturing of highly accurate molds and they do not shrink with time, thereby maintaining the accuracy over time.So nearly all mold manufactures choose cnc router machine.

The first thing about a CNC router that really stands out from a CNC mill is the scale. A CNC router can have a machinable area of 60" X 216" X 8".

While the CNC router is not suited for cutting ferrous materials, it excels at cutting composite prototyping boards, plastics, carbon fiber and even non-ferrous metals with the proper accessories.

A CNC router can allow you to do larger scale mold masters and cavities, and in turn, service markets currently being ignored by most mold and pattern shops. Applications have included mold masters for 1/5 scale RC helicopter FRP molds, 6' x 10' centerboard masters for sailboats, antique grille masters for sand casting and various automotive application molds and masters for vacuum forming. The versatility of a CNC router is amazing as it excels at cutting smaller molds and masters with reliable tolerances in the .003 to .006" range.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com