close

Choose Your Site

Global

Social Media

DESCRIPTION

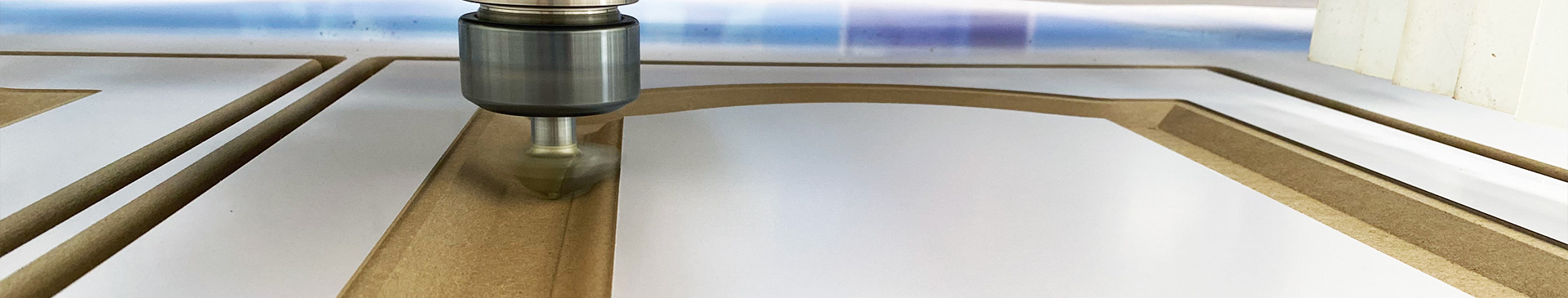

The sofa manufacturing industry is rapidly evolving toward automation, precision, and high-speed production. This video demonstrates an industrial-grade CNC router machine integrated with a 6-axis robot loading system, forming a fully automated CNC production cell engineered specifically for sofa frame and sofa skeleton cutting.

This smart CNC system is designed for factories producing solid wood sofa frames, plywood sofa structures, and upholstered furniture internal framework components. The robotic arm handles automatic material loading and unloading, feeding wooden panels into the CNC router with high stability and accuracy. This enables continuous unmanned production, eliminating manual feeding delays and maximizing machine utilization for 24/7 industrial operation.

The CNC router performs multi-process machining optimized for sofa structural parts:

High-speed contour cutting for curves, profiles, and complex sofa frame outlines

Slotting and grooving for connector fitting and frame assembly joints

Tenon and mortise cutting for strong interlocking sofa structure joints

Drilling and punching of precise assembly holes

Precision tolerance control, ensuring repeatable and consistent dimensions

These capabilities make it ideal for processing both standard and customized sofa frame designs at scale.

This CNC cutting system supports a wide range of boards commonly used in sofa frame production:

Solid wood panels (rubber wood, pine, birch, etc.)

Plywood and laminated boards

MDF / HDF

OSB

Engineered wood boards

The robot + CNC integrated line delivers major production advantages frequently searched by global buyers:

·

Reduced labor cost through unmanned robotic feeding

Higher production efficiency with uninterrupted workflow

Increased output capacity for mass production factories

Reduced material waste through optimized CNC nesting software

Improved workplace safety by minimizing manual handling

Clean cutting edges and accurate sizes, reducing rework rate

Stable heavy-duty machine frame for long-term operation

Easy maintenance access and modular robot-CNC interface

Remote technical assistance and operator training support

Fast spare parts supply for overseas markets

| Series | NA-48L | NA-49L |

| Working size | 1220*2440*150mm | 1220*2800*150mm |

| Table size | 1220*2440mm *2 | 1220*2800mm *2 |

| Transmission | X Y rack and pinion,Z ball screw | X Y rack and pinion,Z ball screw |

| Spindle | 12kw | 12kw |

| Travelling speed | 50m/min | 50m/min |

| Working speed | 20m/min | 20m/min |

| Driving system | SYNTEC | SYNTEC |

| Controller | Syntec | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH | AC380V/220V,50/60HZ,3PH |

| Dimension | 6200*2260*2150mm | 6320*2260*2150mm |

DESCRIPTION

The sofa manufacturing industry is rapidly evolving toward automation, precision, and high-speed production. This video demonstrates an industrial-grade CNC router machine integrated with a 6-axis robot loading system, forming a fully automated CNC production cell engineered specifically for sofa frame and sofa skeleton cutting.

This smart CNC system is designed for factories producing solid wood sofa frames, plywood sofa structures, and upholstered furniture internal framework components. The robotic arm handles automatic material loading and unloading, feeding wooden panels into the CNC router with high stability and accuracy. This enables continuous unmanned production, eliminating manual feeding delays and maximizing machine utilization for 24/7 industrial operation.

The CNC router performs multi-process machining optimized for sofa structural parts:

High-speed contour cutting for curves, profiles, and complex sofa frame outlines

Slotting and grooving for connector fitting and frame assembly joints

Tenon and mortise cutting for strong interlocking sofa structure joints

Drilling and punching of precise assembly holes

Precision tolerance control, ensuring repeatable and consistent dimensions

These capabilities make it ideal for processing both standard and customized sofa frame designs at scale.

This CNC cutting system supports a wide range of boards commonly used in sofa frame production:

Solid wood panels (rubber wood, pine, birch, etc.)

Plywood and laminated boards

MDF / HDF

OSB

Engineered wood boards

The robot + CNC integrated line delivers major production advantages frequently searched by global buyers:

·

Reduced labor cost through unmanned robotic feeding

Higher production efficiency with uninterrupted workflow

Increased output capacity for mass production factories

Reduced material waste through optimized CNC nesting software

Improved workplace safety by minimizing manual handling

Clean cutting edges and accurate sizes, reducing rework rate

Stable heavy-duty machine frame for long-term operation

Easy maintenance access and modular robot-CNC interface

Remote technical assistance and operator training support

Fast spare parts supply for overseas markets

| Series | NA-48L | NA-49L |

| Working size | 1220*2440*150mm | 1220*2800*150mm |

| Table size | 1220*2440mm *2 | 1220*2800mm *2 |

| Transmission | X Y rack and pinion,Z ball screw | X Y rack and pinion,Z ball screw |

| Spindle | 12kw | 12kw |

| Travelling speed | 50m/min | 50m/min |

| Working speed | 20m/min | 20m/min |

| Driving system | SYNTEC | SYNTEC |

| Controller | Syntec | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH | AC380V/220V,50/60HZ,3PH |

| Dimension | 6200*2260*2150mm | 6320*2260*2150mm |

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com