close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-02 Origin: Site

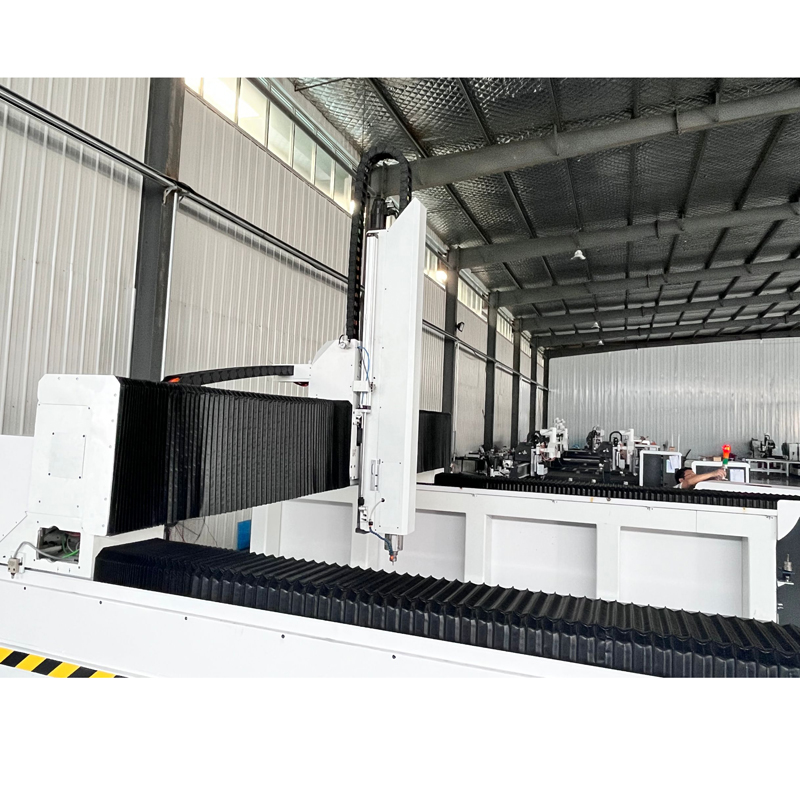

Are you looking for ways to enhance your manufacturing process with precision cutting and shaping? CNC routers are an ideal solution, offering accuracy, versatility, and automation. With the increasing demand for customized products, CNC routing has emerged as an indispensable tool in many industries. But what exactly is CNC routing? And how can a 3 axis CNC router be the key to transforming your business?

In this article, we’ll explore the definition of CNC routing, the different types of CNC routers available, their applications across various industries, and the essential tools used in CNC routing. Whether you are considering CNC routing for your business or simply want to learn more about its capabilities, this post has you covered.

CNC routing is a computer-controlled machining process used for cutting, carving, and shaping materials such as wood, plastics, metals, and foams. It employs a rotating tool to precisely remove material from a workpiece, following programmed instructions provided by a computer system. The “CNC” in CNC routing stands for Computer Numerical Control, which directs the router’s movements based on G-code.

A 3 axis CNC router operates along three axes: X, Y, and Z. This movement allows the router to create cuts, engravings, and carvings in three dimensions, offering exceptional flexibility in the production of intricate parts. Whether you’re cutting a simple geometric shape or creating a detailed custom design, a 3 axis CNC router can handle the task with high precision.

CNC routers use a combination of hardware and software to execute intricate designs. The process begins with creating a digital design on CAD (Computer-Aided Design) software, which is then converted into G-code by CAM (Computer-Aided Manufacturing) software. This G-code directs the CNC router to perform specific movements, such as cutting, engraving, or shaping the material.

Frame and Gantry: Provides the machine's structural integrity and supports the moving parts.

Spindle: Rotates the cutting tool to remove material from the workpiece.

Table/Bed: Holds the workpiece in place while the router works on it.

Motors: Control the movement along the X, Y, and Z axes.

CNC Controller: The brain of the system, translating the G-code into machine movements.

These components work together to ensure that the CNC router delivers precision cuts every time.

CNC routers come in different types, each designed for specific tasks and materials. The most common types include:

Description: These routers move along the X, Y, and Z axes, making them suitable for a wide range of cutting applications on flat materials.

Applications: Woodworking, sign-making, and basic engraving.

Description: In addition to the X, Y, and Z axes, these routers add rotational capability along the X-axis. This additional axis allows for more complex shapes and carvings.

Applications: Used for cylindrical designs, sculptures, and machining on multiple sides of the workpiece.

Description: These advanced machines offer simultaneous movement along five axes, providing the capability to carve intricate designs from any angle.

Applications: Aerospace parts, high-precision components, and artistic sculptures.

Description: These routers are designed to cut specific materials, such as foam, stone, or composites, with specialized tools and settings.

Applications: Ideal for industries such as automotive, aerospace, and marine, where customized parts are essential.

CNC routers are used in various industries due to their versatility and precision. Some of the key applications include:

CNC routers are extensively used for cutting, carving, and shaping wood for furniture, cabinetry, and architectural elements. The precision and repeatability of CNC routing make it ideal for creating intricate designs and high-quality finishes.

CNC routers are perfect for creating detailed signage, including engraving logos, letters, and images on materials like acrylic, wood, and PVC. The ability to work with various materials allows sign makers to produce customized, high-quality signs for businesses, events, and personal use.

CNC routers are invaluable in the prototyping stage of product development, allowing designers to quickly turn digital models into physical parts. In manufacturing, they are used to produce components for a wide range of industries, including automotive, aerospace, and consumer goods.

While CNC routers are not suitable for cutting hard metals like steel or titanium, they can effectively handle softer metals like aluminum and brass. This makes them useful for creating custom parts for machinery and automotive applications.

Artists use CNC routers for creating sculptures, engravings, and other artistic works in materials such as wood, metal, and plastic. The high level of precision makes it possible to execute complex designs that would be difficult to achieve manually.

CNC routers are often used for cutting foams and plastics for products like packaging, insulation, and models. The machines can handle various thicknesses and densities of foam and plastic materials.

The 3 axis CNC router offers several benefits for businesses in terms of efficiency, precision, and cost-effectiveness:

High Precision: CNC routers can achieve a tolerance of ±0.0025mm, making them ideal for intricate designs and components.

Speed and Efficiency: CNC routers can operate continuously without fatigue, speeding up production times and allowing businesses to meet deadlines more easily.

Consistency: CNC routing ensures that each part is cut with the same level of accuracy, reducing the likelihood of human error.

Versatility: CNC routers can work with various materials, including wood, plastic, foam, and soft metals, making them highly adaptable to different industries.

Automation: Once the design is set, CNC routers can operate autonomously, freeing up human resources for other tasks.

Despite their many advantages, there are a few limitations to consider:

Material Restrictions: CNC routers are not suitable for cutting hard metals such as steel or titanium.

Size Limitations: The size of the bed limits the workpiece size, and larger pieces may require specialized machines.

Noise: CNC routers can be loud due to their vacuum systems, which may be an issue in noise-sensitive environments.

To achieve optimal results with CNC routing, it is essential to use the right tools. Some of the key tools include:

Router Bits: Various types of router bits are used for different applications, including straight bits, V-bits, ball nose cutters, and spiral bits.

Workholding Devices: Clamps, vises, and vacuum hold-downs are essential for securing materials during routing.

Dust Collection Systems: These systems help maintain a clean working environment by capturing dust and debris generated during the routing process.

CNC Software: CAD and CAM software are used to design parts and translate them into machine-readable instructions (G-code).

CNC routing is a transformative technology that has revolutionized manufacturing, woodworking, and design. With its ability to work with various materials and produce high-precision parts, a 3 axis CNC router is an invaluable tool for businesses looking to streamline their production processes.

Whether you are in the sign-making, woodworking, or automotive industry, CNC routers offer a level of precision and efficiency that traditional manual methods cannot match. If you're looking for high-quality CNC routing solutions, consider exploring the DWD product offerings to find the right fit for your needs.

A: A 3 axis CNC router can cut wood, plastics, foam, and soft metals like aluminum and brass. It is not suitable for hard metals like steel or titanium.

A: A 3 axis CNC router can achieve a precision of ±0.0025mm, making it ideal for intricate designs and parts that require high accuracy.

A: Industries such as woodworking, sign-making, prototyping, automotive, aerospace, and art and design can all benefit from the precision and efficiency of 3 axis CNC routers.

A: A 3 axis CNC router uses computer programming to control the movement of a spindle with a cutting tool along the X, Y, and Z axes, carving and shaping the material according to the design specifications.

A: While 3 axis CNC routers are versatile and efficient, they may be limited by the size of the workpiece. Larger production runs may require specialized equipment like industrial CNC routers with larger beds or additional axes.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com