close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

Drilling is a vital technique in industries like oil, gas, and construction. Understanding the drilling process ensures efficiency and safety. In this post, you'll learn about the four key steps: planning, drilling, casing, and completion, including the role of CNC Drilling Machines.

The first step in the drilling process is choosing the right site. It’s crucial to analyze the location carefully before any drilling begins. Engineers and geologists study the area’s geology, soil types, and underground formations. They look for signs that indicate the presence of resources like water, oil, or minerals.

Environmental impact is also assessed. This helps ensure the site won’t cause harm to local ecosystems or communities. Proper site selection reduces risks and increases the chances of a successful drilling operation.

Once the site is chosen, the next task is preparing all necessary equipment and materials. This includes drilling rigs, drill bits, pipes, and safety gear. Each piece of equipment must be inspected and tested to confirm it’s in good working condition.

Materials like drilling mud, casing pipes, and cement are gathered and checked for quality. Drilling mud, for example, helps cool the drill bit and carry rock cuttings to the surface. Preparing everything ahead of time prevents delays and equipment failures during drilling.

Safety is a top priority during planning. Teams develop safety protocols to protect workers and the environment. This includes training workers on emergency procedures and proper handling of hazardous materials.

Environmental considerations involve controlling pollution and managing waste. Plans might include measures to prevent spills, reduce noise, and protect local wildlife. Regulatory permits and approvals are also secured during this stage to ensure compliance with laws.

Drilling the borehole is the core step in the drilling process. Several drilling techniques exist, each suited for different purposes and ground conditions:

Rotary Drilling: The most common method. A drill bit attached to a rotating drill string cuts through rock layers. It works well in hard rock and deep wells.

Percussion Drilling: Uses repeated hammering to break rock. Ideal for shallow wells or soft formations.

Auger Drilling: Employs a helical screw blade to remove soil or soft rock. Mostly used for shallow drilling in soil or unconsolidated materials.

Directional Drilling: Allows the drill to follow a curved path to reach targets not directly beneath the rig. Useful in oil and gas industries.

Cable Tool Drilling: An older method where a heavy bit is repeatedly lifted and dropped to crush rock. Still used in some groundwater wells.

Choosing the right technique depends on factors like depth, geology, budget, and the well's purpose.

Drilling requires specialized tools and machines to penetrate underground formations efficiently:

Drill Rig: The main machine providing power, rotation, and support for the drill string.

Drill Bit: The cutting tool at the drill string's end. Bits come in various designs like roller cone, PDC (polycrystalline diamond compact), or diamond bits, tailored for different rock hardness.

Drill Pipe and Drill String: Pipes connect the rig to the bit, transmitting rotation and drilling fluid.

Mud Pumps: Circulate drilling fluid (mud) down the drill string to cool the bit, remove cuttings, and stabilize the borehole.

Blowout Preventer (BOP): A safety device preventing uncontrolled release of fluids from the well.

Measurement Tools: Sensors and logging tools monitor drilling parameters and underground conditions.

Proper maintenance and operation of these tools ensure smooth drilling and reduce downtime.

Drilling can encounter several challenges, but solutions exist to handle them effectively:

Formation Collapse: Loose or weak formations may cave in, blocking the borehole. Using drilling mud with proper density and casing can stabilize the hole.

Lost Circulation: Drilling fluid may leak into porous formations, causing pressure loss. Adding lost circulation materials or adjusting mud properties helps fix this.

Stuck Drill String: The drill pipe can get stuck due to differential pressure or hole collapse. Techniques like jarring tools or reversing circulation assist in freeing it.

Equipment Wear: Drill bits and machinery wear quickly in hard rock. Regular inspection and timely replacement prevent failures.

Environmental Concerns: Drilling fluids and cuttings may contaminate surroundings. Using eco-friendly mud and containment measures mitigate impact.

Operators must monitor drilling conditions continuously and adapt techniques to overcome these obstacles.

Casing plays a vital role in the drilling process. It is a series of steel pipes inserted into the drilled borehole. The main purpose is to stabilize the wellbore walls and prevent them from collapsing. Without casing, loose soil or rock could fall into the hole, causing blockages or damage.

Casing also protects groundwater from contamination by isolating the well from surrounding soil layers. It provides a sealed barrier that keeps drilling fluids and extracted materials safely contained. Additionally, casing allows safe installation of other well components and supports the overall structure of the well.

Most casing pipes are made from steel due to its strength and durability. Steel can withstand high pressures and harsh underground conditions. Sometimes, pipes get coated with corrosion-resistant materials to extend their lifespan.

In some cases, especially for shallow or less demanding wells, casing may be made from PVC or other plastics. These materials resist corrosion and are lighter, making them easier to handle. However, plastic casing is less common in deep or high-pressure wells.

The choice of casing material depends on factors like:

Depth of the well

Type of soil and rock formations

Pressure and temperature underground

Budget constraints

Installing casing requires careful planning and precision. Here’s how it generally works:

Lowering the Casing: After drilling reaches a certain depth, casing pipes are connected and lowered into the borehole. They usually come in sections, joined by threaded connections.

Cementing: Once the casing is in place, cement is pumped down the casing and up the outside between the casing and borehole wall. This seals the space, preventing fluid movement and stabilizing the formation.

Setting and Curing: The cement is allowed to harden, securing the casing firmly. This process can take several hours to days depending on the cement type.

Pressure Testing: After curing, the casing and cement job are tested under pressure to check for leaks or weak spots.

Best practices include:

Using casing centralizers to keep the pipe centered in the borehole, ensuring even cement distribution.

Choosing the correct casing size and grade to match the well’s conditions.

Monitoring cement flow carefully to avoid channels or voids.

Following environmental and safety standards to limit impact.

Proper casing installation ensures the well’s integrity and longevity. It protects the environment and supports safe extraction or water access. Skipping or poorly done casing can lead to costly failures, contamination, or accidents.

Completing the well is the final step in the drilling process, making it ready for its intended use, such as extracting oil, gas, or water. Several techniques exist to finish the well properly:

Perforating: Creating holes in the casing and cement to allow fluids to enter the wellbore. This is common in oil and gas wells to connect the reservoir to the well.

Installing Production Tubing: A smaller pipe placed inside the casing to carry the extracted fluids to the surface efficiently.

Gravel Packing: Placing gravel around the well screen to prevent sand production and stabilize the formation.

Well Stimulation: Methods like hydraulic fracturing or acidizing to improve flow by opening fractures or dissolving rock near the wellbore.

Installing Packers: Devices that seal off sections inside the well to control fluid flow and isolate zones.

Choosing the right completion method depends on the well's purpose, geology, and expected production.

After completion, testing ensures the well functions as planned. Common tests include:

Pressure Testing: Checks the integrity of casing, tubing, and seals to prevent leaks.

Flow Testing: Measures the rate and quality of fluids produced, confirming well productivity.

Logging: Using specialized tools to gather data about the well’s structure, fluid content, and formation properties.

Wellhead Inspection: Examines valves and equipment at the surface for proper operation.

These evaluations help identify problems early and guide any needed adjustments.

Maintaining the well over time is crucial for safety and efficiency. Key practices include:

Regular Monitoring: Tracking pressure, flow rates, and equipment condition to spot issues.

Routine Maintenance: Cleaning, repairing, or replacing parts like pumps, valves, and tubing.

Corrosion Protection: Applying coatings or using corrosion inhibitors to extend equipment life.

Environmental Safeguards: Preventing leaks or spills through containment systems and emergency plans.

Compliance with Regulations: Following laws and standards to protect workers and the environment.

Proper completion and ongoing care ensure the well remains productive and safe for years.

Drilling involves complex machinery and precise operations, so technical and mechanical issues often arise. One common problem is equipment failure, such as drill bit wear or motor breakdowns. Drill bits wear out quickly, especially when cutting through hard rock. This slows progress and increases costs. Regular maintenance and timely replacement help reduce downtime.

Another challenge is borehole instability. Sometimes, the walls of the hole collapse or cave in due to loose soil or fractures. This can trap equipment or block the hole entirely. Using proper drilling mud and casing supports the borehole and keeps it stable.

Stuck drill strings also cause delays. The drill pipe can get stuck due to pressure differences or debris. Operators use special tools like jars or reverse circulation to free stuck pipes. Managing drilling parameters carefully helps avoid this issue.

Lastly, lost circulation happens when drilling fluid leaks into porous formations. This reduces pressure needed to remove cuttings and cool the bit. Adding lost circulation materials or adjusting mud properties can fix this.

Drilling impacts the environment, so strict regulations govern the process. One major concern is contamination of groundwater. If casing or seals fail, harmful substances can leak into water supplies. Proper casing installation and cementing prevent this.

Waste management is another challenge. Drilling produces cuttings and used fluids that must be handled safely. Operators need containment and disposal plans to avoid soil or water pollution.

Noise and air pollution affect nearby communities. Controlling noise levels and emissions is essential to comply with regulations and maintain good relations.

Obtaining permits and meeting environmental standards can delay projects. Companies must conduct environmental impact assessments and follow local laws carefully.

Overcoming these challenges requires planning, technology, and skilled teams. Here are some effective strategies:

Preventive Maintenance: Regular checks and repairs keep equipment in top shape, reducing breakdowns.

Advanced Drilling Fluids: Using specially formulated mud stabilizes boreholes and controls pressure.

Real-Time Monitoring: Sensors track drilling conditions, allowing quick adjustments to avoid problems.

Proper Training: Skilled operators know how to handle equipment and respond to emergencies.

Environmental Safeguards: Implementing strict waste disposal, spill prevention, and noise control measures.

Regulatory Compliance: Early engagement with authorities ensures permits and inspections go smoothly.

Use of Technology: Modern tools like automated drilling rigs and data analytics improve accuracy and efficiency.

By combining these approaches, drilling teams can reduce risks, protect the environment, and complete projects successfully.

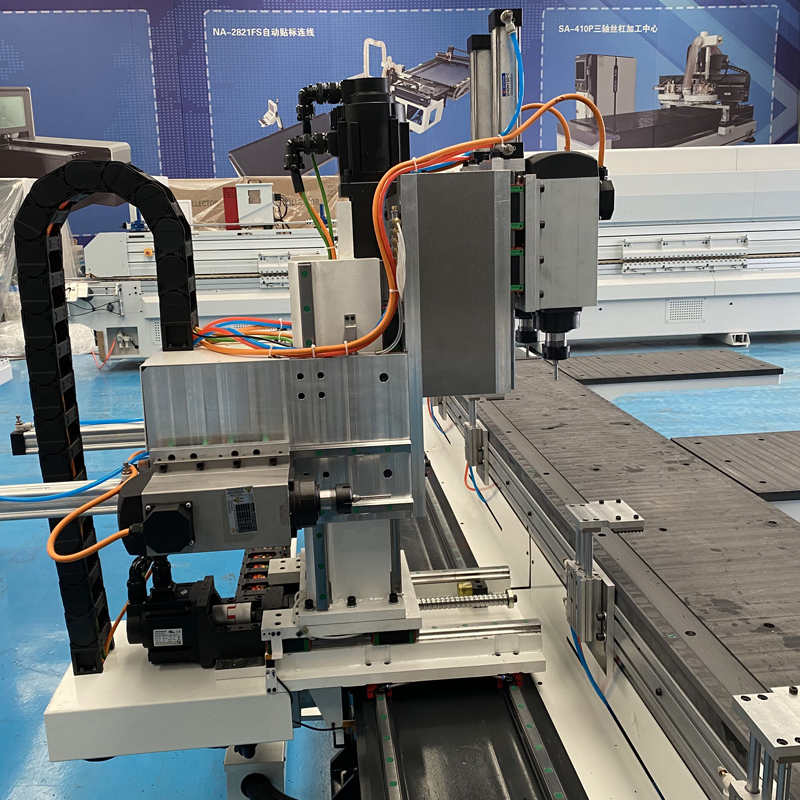

CNC (Computer Numerical Control) drilling machines have transformed the drilling process. They use computer programs to control drill movements precisely. This automation means the drill can follow complex paths and make accurate holes repeatedly without human error.

In industries like manufacturing, aerospace, and construction, CNC drilling machines boost productivity. They handle tasks faster and more consistently than manual drilling. The machines can work on various materials, from metals to plastics, adapting easily to different project needs.

CNC technology also allows for intricate designs. For example, it can drill multiple holes of varying sizes and depths in one setup. This reduces setup times and improves overall efficiency.

Automation in drilling brings several key advantages:

Increased Accuracy: CNC machines drill holes exactly where programmed, reducing mistakes.

Higher Speed: Automated systems work faster than humans, cutting production times.

Consistency: Each hole is identical, ensuring quality across large batches.

Reduced Labor Costs: Machines require less manual input, lowering labor expenses.

Enhanced Safety: Operators stay away from moving parts, reducing injury risks.

Flexibility: Programs can be changed quickly for different drilling patterns or materials.

Precision also improves the final product's quality. For instance, in oil and gas drilling, precise boreholes reduce wear on equipment and improve extraction efficiency. In manufacturing, accurate holes ensure parts fit perfectly, avoiding costly rework.

The drilling industry continues evolving through new technologies:

Automation and Robotics: Fully automated rigs and robotic arms will handle more drilling tasks, reducing human involvement.

Smart Drilling Systems: Sensors and AI will monitor drilling conditions in real-time, adjusting parameters to optimize performance and prevent problems.

Advanced Materials: New drill bits made from super-hard materials will last longer and drill faster.

Energy Efficiency: Electric and hybrid drilling machines will reduce fuel consumption and emissions.

3D Printing Integration: Custom drill parts and tools could be printed on-site, speeding repairs and customization.

Remote Operation: Operators will control rigs from safe, remote locations, improving safety and allowing work in harsh environments.

These trends aim to make drilling safer, faster, and more environmentally friendly.

The drilling process involves four key steps: planning and preparation, drilling the borehole, installing the casing, and completing the well. Efficient drilling practices are crucial for minimizing risks and ensuring successful operations. As technology advances, the future of drilling promises increased safety, precision, and environmental sustainability. Companies like DWD MECHATRONICS CO.,LTD provide innovative solutions that enhance drilling efficiency and reliability, offering products that deliver exceptional value through cutting-edge technology and superior performance.

A: Site selection and analysis.

A: It stabilizes the wellbore and prevents contamination.

A: Automated machines that use computer programs for precise drilling.

A: It increases accuracy, speed, and safety while reducing labor costs.

A: Equipment failure and borehole instability.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com