close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

Are you still relying on traditional woodworking methods to build cabinets? It’s time to explore the revolutionary power of Cabinet making CNC routers. These cutting-edge machines are transforming the way cabinet makers work, offering unparalleled precision, efficiency, and versatility. If you’re wondering how a Cabinet making CNC router can benefit your business, you're in the right place.

In this article, we’ll dive deep into the advantages of using CNC wood routers for cabinetry, why they’re essential for modern woodworking, and how DWD’s products stand out in the industry. By the end, you’ll have a clear understanding of how investing in a Cabinet making CNC router can elevate your business.

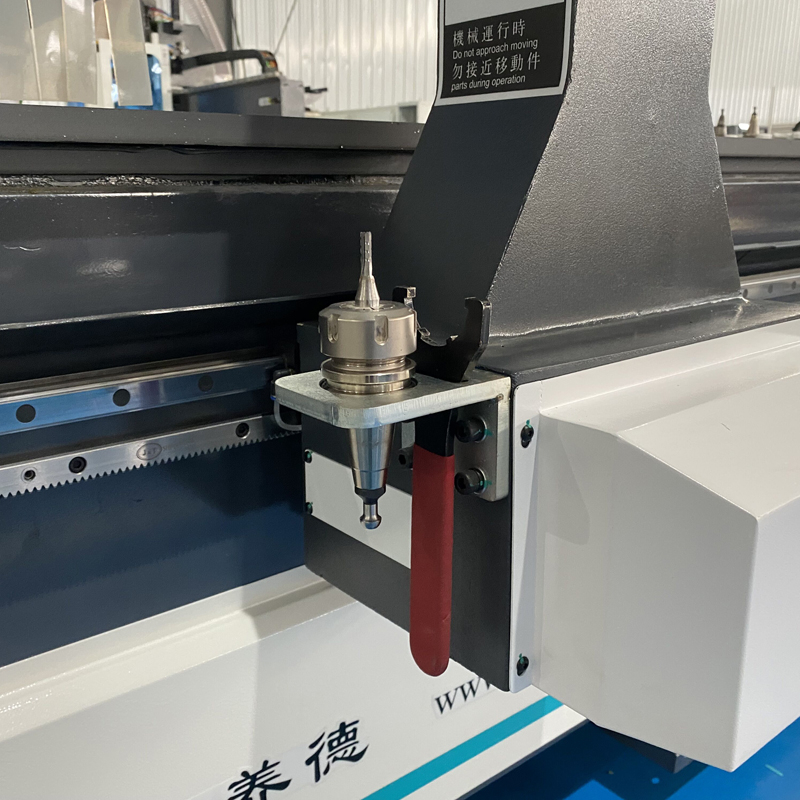

One of the most significant advantages of using a Cabinet making CNC router is the level of precision it brings to your work. Traditional cabinet making often relies on manual tools and techniques that can introduce errors, affecting the overall quality of the finished product. With a CNC wood router, the cutting paths are programmed with exact measurements, ensuring each cut is made with millimeter-perfect accuracy.

This precision leads to consistent results, meaning you can produce identical parts with little to no variation. Whether you’re cutting cabinet doors, drawers, or panels, CNC wood routers help ensure that every piece fits perfectly every time.

Accuracy: Automated cutting and carving to the finest degree.

Consistency: Achieve the same results on every part, every time.

Quality: Produce clean edges and flawless cuts that reduce rework.

In the competitive world of cabinetry, time is money. Traditional methods of cabinet making can be labor-intensive and time-consuming, especially for complex cuts or intricate designs. Cabinet making CNC routers speed up the process significantly. These machines work continuously, automating tasks such as cutting, drilling, and shaping, which would typically take hours by hand.

For example, a CNC wood router can cut multiple pieces at once, drastically reducing production time. This increased speed not only helps meet tight deadlines but also allows businesses to take on more projects and increase their overall productivity.

Faster Turnaround: Machines operate continuously without the need for breaks or rest.

Multi-tasking: CNC routers can handle several tasks simultaneously.

Increased Output: Produce more cabinets in less time, maximizing profits.

Another standout feature of Cabinet making CNC routers is their versatility. These machines can execute a wide variety of tasks, from basic cuts to complex engravings and intricate designs. Cabinet makers often face the challenge of fulfilling customer requests for custom designs, and a CNC wood router makes this process much easier.

With the ability to program virtually any design, a CNC wood router can cut custom shapes, create decorative inlays, engrave logos, and even craft unique edge profiles. This versatility allows businesses to cater to a broader range of client needs, from traditional cabinet styles to more modern, creative concepts.

Custom Designs: Create bespoke pieces with intricate detailing.

Adaptability: Switch between different tasks like routing, engraving, and drilling with ease.

Complexity: Handle design complexities that would be difficult or impossible manually.

While the upfront cost of a Cabinet making CNC router might seem substantial, the long-term cost savings are undeniable. First, these machines drastically reduce the need for manual labor, which in turn lowers labor costs. Workers can focus on other aspects of production, such as assembly and finishing, rather than spending time on repetitive cutting tasks.

Second, the accuracy and efficiency of CNC wood routers reduce material waste. Traditional methods often lead to mistakes that result in wasted wood or expensive errors. With a CNC router, each piece is cut precisely as needed, minimizing waste and maximizing the use of raw materials.

Reduced Labor Costs: CNC routers require fewer workers to complete the same amount of work.

Lower Material Waste: Precision cutting means less waste and higher yield from each piece of material.

Long-Term Investment: The machine’s efficiency saves money in the long run, offsetting initial costs.

Safety is a top priority in any workshop, and Cabinet making CNC routers are designed with several safety features to protect operators. These machines come with integrated systems such as emergency stop buttons, dust collection mechanisms, and automated tool height adjustments that enhance the overall safety of the workplace.

By minimizing human intervention in dangerous tasks like cutting and routing, CNC wood routers also reduce the risk of accidents and injuries that could occur with manual tools. Operators can feel confident knowing they are working with advanced, safe technology that prioritizes both productivity and safety.

Automated Safety: Safety features like emergency stops and tool height adjustments.

Protective Equipment: Many CNC routers come with safety guards and covers to prevent injuries.

Reduced Human Error: By automating the process, there is less room for accidents or unsafe practices.

A Cabinet making CNC router is a robust investment built for long-term use. Unlike manual tools that require frequent maintenance and replacement, CNC routers are designed for durability and minimal upkeep. With proper maintenance, these machines can operate for years without losing performance or accuracy.

Modern CNC wood routers are built with high-quality materials, ensuring they can handle demanding tasks like cutting through dense wood and running for long hours. Their reliability makes them an essential tool for any cabinet-making business looking to scale production without compromising on quality.

Durability: Built to withstand heavy use over many years.

Low Maintenance: Requires minimal repairs, making it a cost-effective solution.

Continuous Operation: CNC routers can work for extended periods without needing breaks.

Sustainability is becoming increasingly important in today’s world, and Cabinet making CNC routers can help businesses reduce their environmental footprint. The precision of CNC routers ensures that there is minimal material wastage, and the automated process helps optimize energy usage.

Additionally, many CNC wood routers are equipped with eco-friendly features like dust collection systems that reduce air pollution in the workshop. By investing in a Cabinet making CNC router, businesses can contribute to sustainability efforts while improving efficiency and productivity.

Less Waste: Precision cuts mean fewer offcuts and wasted material.

Eco-Friendly: Dust collection systems and energy-efficient technology.

Sustainability: CNC routers contribute to greener business practices.

The benefits of using a Cabinet making CNC router for your woodworking business are clear. From enhanced precision and speed to cost savings and improved safety, these machines offer unmatched advantages over traditional methods. If you're looking to improve your productivity, reduce waste, and create custom designs with ease, investing in a CNC wood router is a game-changer.

DWD’s Cabinet making CNC routers are designed with the latest technology, offering businesses like yours the tools to thrive in a competitive industry. With their precision, versatility, and cost-effectiveness, these machines can take your cabinetry projects to new heights.

A: A CNC wood router is used to cut, shape, drill, and carve wood with high precision, making it ideal for producing cabinets and custom woodworking projects.

A: Yes, CNC routers can execute intricate patterns, engravings, and custom designs, offering flexibility and precision that traditional tools can’t match.

A: Modern CNC routers are user-friendly and come with intuitive interfaces. However, proper training in machine operation and programming is recommended for optimal results.

A: CNC routers are programmed to make precise cuts, minimizing material wastage. This ensures that every piece is used efficiently, leading to cost savings and reduced environmental impact.

A: Yes, CNC wood routers are equipped with several safety features, including emergency stop buttons and dust collection systems, making them safer than traditional manual tools.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com