close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-14 Origin: Site

Whether you're a workshop just starting out or an established manufacturer scaling operations, choosing the right CNC router table size is critical. Too small, and you’ll battle with material constraints. Too large, and you might be wasting valuable space and energy.

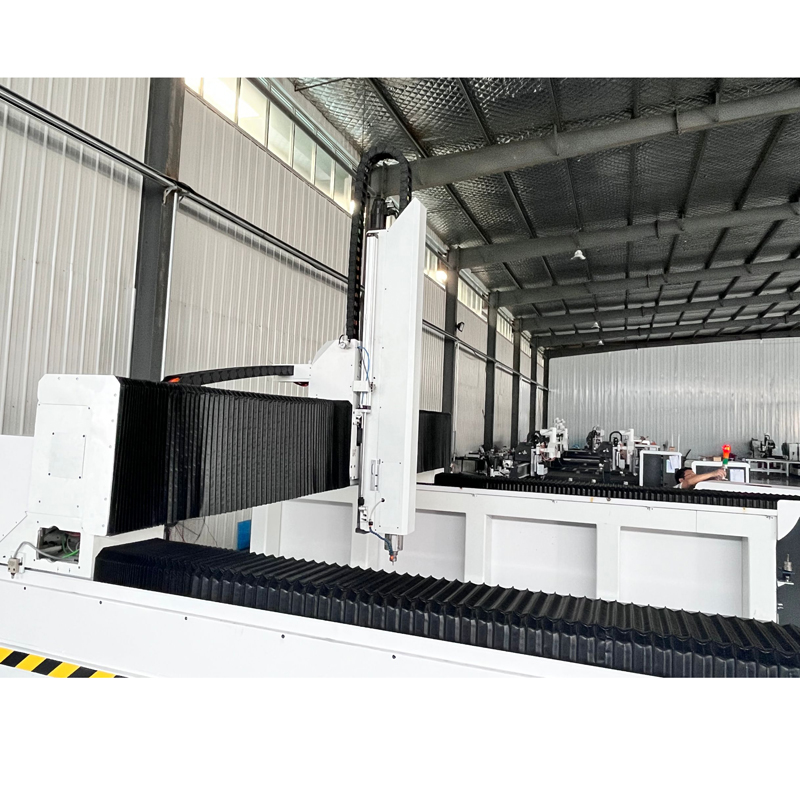

In this post, we’ll explore how businesses — from niche crafters to industrial producers — can determine the best CNC router table sizes to optimize their investment. We’ll focus on how the choice ties into the performance of your 3 axis cnc router and how the right size can help you scale smarter, faster, and more profitably.

Choosing the right CNC router table size is about more than just space. It influences everything: cutting precision, spindle flexibility, workload efficiency, and ultimately your return on investment.

When paired with a high-performance 3 axis cnc router, a well-matched table size can increase throughput while reducing labor time and material waste. Here’s why:

Larger tables enable bigger workpieces, reducing segmentation or repositioning errors.

Smaller tables support precision projects and tighter control — ideal for engraving or complex detailing.

The match between table size and material ensures optimal cutting paths, fewer tool changes, and improved project timelines.

So, how do you know which size works for your business?

Below is a table summarizing typical sizes and their most suited applications:

| Table Size | Ideal For | Compatible with 3 Axis CNC Router? |

|---|---|---|

| 2×3 ft | Custom crafts, badges, engraving | ✅ Yes |

| 4×4 ft | Medium-sized signs, furniture components | ✅ Yes |

| 4×8 ft | Cabinetry, wall panels, full sheet cutting | ✅ Yes |

| 5×10 ft | High-volume, industrial panel work | ✅ Yes |

| 2030 or larger | Complex mold cutting, nested production | ✅ Yes |

Each of these sizes complements the functionality of a 3 axis cnc router, but they differ significantly in output capabilities.

Start with your material. What is the largest sheet you regularly cut? The table should accommodate that size comfortably with buffer room for clamping systems and tool clearance.

If you work with standard 4x8 ft plywood or MDF sheets, then a 4x8 ft router table makes sense. Cutting those sheets on a smaller table would require repositioning and increase error margins.

High-output environments like furniture factories or signage shops require faster turnover. Larger CNC router tables enable batch processing of multiple parts simultaneously. With a 3 axis cnc router, this translates into fewer tool lifts, less downtime, and consistent quality.

For low-volume or custom one-off jobs, smaller table sizes provide precise control and lower operational overhead.

Don’t underestimate this. A 5×10 ft table may require up to 20 square meters of clear floor space once you factor in loading zones, control boxes, dust collection, and material handling.

Make sure your workspace supports not only the machine footprint but also ergonomic and safe movement around it.

You may not need the largest size now, but will your business scale? Choosing a modular 3 axis cnc router table — where you can expand or upgrade components — ensures your setup evolves as your operation grows.

At the heart of every table decision is the machine you’re pairing it with. The 3 axis cnc router remains the most trusted and versatile system in modern fabrication.

It allows controlled movement along X, Y, and Z axes — ideal for cutting, drilling, engraving, and shaping flat and slightly contoured surfaces. But its full potential is only unleashed when matched with the right table size.

Here’s how table size amplifies the performance of your 3 axis cnc router:

Smaller tables help stabilize lightweight materials like acrylic, PVC, and foam.

Larger tables give space for simultaneous part nesting and multi-tool operations.

Optimal table selection reduces the number of passes and boosts cut quality.

Investing in a precise, rigid, and durable 3 axis cnc router table setup means faster jobs, less waste, and higher accuracy.

How does table size tie into day-to-day operational efficiency? Here’s a breakdown:

| Efficiency Factor | Small Table (2x3, 4x4) | Large Table (4x8, 5x10) |

|---|---|---|

| Setup Time | Low | Moderate |

| Material Waste | Low to Moderate | Low |

| Batch Production | Limited | High |

| Tool Change Frequency | Higher | Lower |

| Floor Space Requirement | Low | High |

| Operator Fatigue | Low | Higher (with manual loading) |

If your operation thrives on single-piece, customized work, a smaller table with a solid 3 axis cnc router could outperform larger setups in terms of cost-efficiency. But for mass production and nested layouts, bigger tables save more in the long term.

Another major consideration when choosing table sizes for your 3 axis cnc router is the range of compatible tools.

With more table surface area, you can integrate:

Rotary axes for cylindrical engraving

Vacuum hold-downs to secure large sheets

Automatic tool changers to swap bits mid-operation

Dust extraction arms without blocking movement

This leads to faster cycle times and higher-quality results — especially in demanding industries like signage, cabinetry, or composite machining.

Modern CNC setups are evolving rapidly, and router table configurations are no exception. Some key trends include:

Compact industrial tables with high-precision 3 axis cnc router modules for urban workshops

Heavy-duty frame construction on larger tables to minimize vibration and distortion

Hybrid tables that combine vacuum beds and T-slot systems for flexible clamping

Smart monitoring sensors embedded in table surfaces to track temperature and vibration

Your business can gain competitive edge by pairing these innovations with a well-optimized table size.

The right table size ensures compatibility with your most-used materials. Here's a guide:

| Material Type | Recommended Table Size | Rationale |

|---|---|---|

| Acrylic, PVC | 2x3 or 4x4 ft | Small formats, precision cuts |

| Plywood, MDF | 4x8 ft | Full panel nesting |

| Solid Wood Panels | 4x8 or 5x10 ft | Large furniture components |

| Aluminum Sheets | 4x4 or 4x8 ft | Stability and clamping support |

| Foam Blocks | 2030 and larger | Mold production, 3D shaping |

Always match your table size to your dominant material format to avoid resizing, re-clamping, or scrap waste.

Large CNC router tables experience higher wear, especially under continuous loads. Investing in:

Steel-reinforced gantries

Ball screw systems for stability

Proper dust extraction pathways

Regular lubrication of linear bearings

…can extend your machine’s lifespan and maintain peak performance for your 3 axis cnc router.

Smaller tables, on the other hand, are easier to clean, recalibrate, and repair — often making them better suited for agile workshops or mobile production units.

Choosing the best CNC router table size for your business is a strategic decision — one that directly affects efficiency, quality, and growth.

When paired with a high-quality 3 axis cnc router, the right table size empowers you to do more, with less waste and faster turnaround.

DWD specializes in durable, high-precision CNC solutions with tailored table sizes. Whether you need compact control or industrial-level performance, our 3 axis cnc router systems deliver reliable results.

A: Our machines can handle wood, plastic, foam, composites, and soft metals with consistent precision.

A: Yes. DWD offers flexible CNC router configurations tailored to your specific material and space requirements.

A: Larger tables need regular lubrication, dust control, and alignment checks to maintain precision over time.

A: A larger table allows more freedom for multi-bit operations and better distribution of spindle force across materials.

A: We offer installation guidance, training, and lifetime technical support to ensure your CNC investment pays off.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com