close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

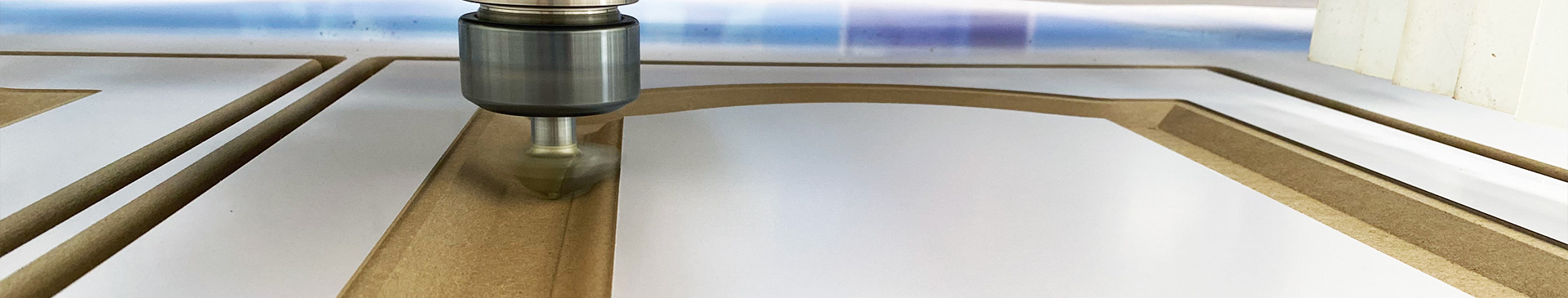

Cutting acrylic with a CNC router can be both incredibly rewarding and surprisingly challenging. Did you know that improper settings or tool choices could cause your acrylic to melt or chip? Whether you're a beginner or seasoned fabricator, mastering acrylic machining is essential to creating high-quality parts.

In this post, we’ll break down the best practices for cutting acrylic with your CNC router. You’ll learn how to choose the right materials, optimize your machine setup, and avoid common pitfalls. This article is especially valuable for those using a Cabinet making cnc router, where precision and clarity are critical.

Acrylic, also known as PMMA (Polymethyl Methacrylate), is a lightweight, durable, and highly transparent plastic. It’s a popular alternative to glass due to its shatter resistance and optical clarity.

There are two main types:

| Type | Description | Best Use Case |

|---|---|---|

| Cast Acrylic | More rigid, resistant to heat, offers better surface finish | Precision parts, display panels |

| Extruded Acrylic | More affordable, consistent in thickness | Simple signage, cabinet covers |

Understanding the type you’re working with will directly influence the quality of your cut, especially if you're operating a Cabinet making cnc router for high-end furniture or panel production.

Before you make your first cut, preparation matters.

Secure Your Acrylic: Always use vacuum tables or rubber-padded clamps to hold your sheet. Vibration leads to irregular edges.

Clean the Surface: Remove dust or film. Even small debris can cause melting or tool marks.

Masking Tape: Apply low-adhesion masking tape to prevent chipping and reduce friction heat.

Plan for Cooling: Keep compressed air or misting systems ready to maintain material temperature.

These steps are especially important in the context of Cabinet making cnc router operations, where the finished visual quality must be flawless.

Tool selection can make or break your project.

| Bit Type | Best For | Notes |

|---|---|---|

| Solid Carbide O-Flute | General cutting | Ejects chips efficiently |

| Single Flute Spiral Upcut | Deep cuts | Avoids chip buildup |

| 60° Engraving Bit | Detail work | Ideal for logos or fine lines |

Avoid woodworking bits at all costs—they’ll melt acrylic and leave rough edges. Always choose bits made specifically for plastics when using your Cabinet making cnc router.

Tuning your machine properly is essential. Acrylic is sensitive to heat and friction.

| Parameter | Recommended Range |

|---|---|

| Feed Rate | 75–300 IPM |

| RPM | 18,000 |

| Cut Depth | ½ the bit diameter |

| Passes | Multiple shallow passes preferred |

Tips:

A higher RPM requires a faster feed rate.

Use ramping instead of plunge cuts.

Keep a consistent motion to avoid heat buildup.

These settings should be dialed in based on the bit size, acrylic thickness, and specific application—especially in cabinet paneling.

Chips that don’t get cleared away can re-weld into the material. Here’s how to manage them effectively:

Use Air Assist: Blow chips away while cooling the bit.

Avoid Pauses: Keep the cut continuous to prevent heat spikes.

Upgrade Your Dust Collection: Fine acrylic particles can damage sensitive components over time.

Efficient chip removal is essential for any Cabinet making cnc router cutting thick or layered acrylic components.

Your router isn't limited to just straight cuts. You can engrave logos, icons, or text with incredible precision.

Use a 60° engraving bit

Shallow depth: 0.01"–0.02"

Slower feed rate (50–100 IPM) for better accuracy

For advanced cabinet-making applications, you can even create layered 3D acrylic inlays to add stunning visual depth.

Proper hold-down techniques reduce vibration and increase accuracy.

Vacuum Tables: Ensure full-sheet stability

Double-Sided Tape: Works for small or thin panels

Edge Supports: Prevent flexing during engraving

Securing is particularly vital when the acrylic is part of decorative cabinet doors or lighting fixtures using your Cabinet making cnc router.

A good cut doesn’t always mean a polished finish. Here’s how to perfect the results:

Polishing: Use a buffing wheel with fine abrasive

Flame Polishing: A propane torch can restore clarity—but use with caution

Sanding: Start with 800 grit, finish with 1500+

Smooth, glossy edges are a hallmark of high-quality cabinet production, especially on transparent or colored panels.

Mistakes can ruin your material—or worse, your machine.

Cutting Too Deep: Leads to melting or bit breakage

Using Wood Bits: Creates rough, jagged edges

Skipping Test Cuts: Always test on a spare piece first

Ignoring Chip Load: Leads to dull bits and overheating

Every Cabinet making cnc router operator should audit these issues before starting high-volume runs.

Acrylic adds a modern, premium feel to cabinetry.

Cabinet Door Inserts: Colored or frosted acrylic for a sleek look

Backlit Panels: Combine LEDs with clear acrylic

Display Cabinets: Transparent protection for valuables

Decorative Dividers: Laser-engraved or router-cut panels

With the right CNC router, these elements are easily scalable and repeatable in your production flow.

Maintaining your tools and router settings saves time and money:

Regular Bit Replacement: Acrylic dulls bits faster than wood

Scheduled Maintenance: Keep the spindle, bearings, and vacuum system clean

Software Updates: Toolpath optimization reduces machine strain

Long-term cabinet making relies on efficient workflows. DWD’s solutions make that possible.

Software plays a crucial role in generating accurate toolpaths:

CAM Software: Offers simulation to prevent tool crashes

V-Carve Pro: Great for both 2D and 3D engraving

AutoNest Tools: Help with acrylic sheet optimization

Your Cabinet making cnc router performs best when paired with intelligent toolpath design.

| Problem | Likely Cause | Solution |

|---|---|---|

| Melted Edges | Too slow feed / dull bit | Increase feed, replace bit |

| Chipping | Wrong bit or no masking | Switch to O-flute, use tape |

| Rough Cuts | Vibration / loose sheet | Check hold-down system |

| Tool Breakage | Overloaded bit | Reduce pass depth, improve cooling |

Acrylic use is growing in modern furniture design.

Smart Kitchens: Transparent doors with embedded LEDs

Minimalist Offices: Frosted acrylic dividers

Retail Displays: Embedded lighting with clear panels

The rise in demand aligns with the flexibility of Cabinet making cnc router systems tailored for these jobs.

DWD provides industrial-grade CNC routers optimized for cabinet making and acrylic machining. With stable gantry structures, vacuum hold-down systems, and precision spindles, our machines deliver consistently clean cuts and fine engravings.

Our customer support, software compatibility, and custom router solutions ensure that whether you’re a small workshop or an industrial plant, you get tools that match your goals.

Cutting acrylic doesn’t have to be difficult. With the right router, tool settings, and techniques, you can turn simple acrylic sheets into flawless cabinet parts or creative showpieces. Whether you're fabricating modern door inserts or backlit displays, knowing how to optimize every step of your process is key.

At DWD, we offer reliable, high-performance Cabinet making cnc router solutions that support your craftsmanship and your business growth. Our machines are built for precision, built for durability—and built for you.

A: Cast acrylic offers better surface finish and rigidity, making it ideal for visible cabinet components and decorative inserts.

A: Yes, DWD routers come with high gantry clearance and strong spindles, perfect for processing thick or layered acrylic sheets.

A: Use an O-flute bit, increase feed rate, and apply cooling with air or mist during the cut.

A: Many of our models come standard with multi-zone vacuum tables to ensure maximum material stability during cutting.

A: Absolutely. Pair our routers with engraving bits and V-Carve Pro software for clean, precise results on acrylic surfaces.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com