close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-16 Origin: Site

Ever wondered which machine truly fits your woodworking business — a CNC nesting machine or a traditional wood CNC router?

In a time when automation and precision are key to staying competitive, many manufacturers face this critical choice. The overlap between these two machines often causes confusion. They both cut, engrave, and process wood, but their purpose, structure, and outcomes can be vastly different.

In this post, you’ll learn what distinguishes a cnc nesting machine from a wood cnc router — from structural design to industry application. We’ll break down their functions, automation capabilities, and configuration differences, and guide you step-by-step toward the right machine for your production needs.

A CNC nesting machine is an advanced woodworking solution built for large-scale panel processing. It cuts entire boards into various parts, following optimized layout patterns (called "nesting") generated by design software. These machines usually feature:

Automatic loading/unloading systems

High-speed, high-precision cutting

Multi-zone vacuum tables

Multiple spindles or tool changers

They're ideal for mass custom furniture production, especially for cabinets, wardrobes, and modular units.

A wood CNC router is a more general-purpose tool. It specializes in 2D/3D carving, engraving, and cutting of wood materials. These routers are suitable for:

Decorative carvings

Artistic wood pieces

Relief engraving

Small furniture projects

They come in various sizes and axis configurations (3, 4, 5 axis), and while powerful, they are often manually operated and have fewer automation features.

| Feature | CNC Nesting Machine | Wood CNC Router |

|---|---|---|

| Primary Function | Cutting panels for furniture assembly | Engraving, carving, and small-scale cutting |

| Automation | High (auto load/unload, labeling, nesting) | Low to moderate (manual setup required) |

| Software Integration | Specialized nesting software | General CAD/CAM software |

| Worktable Type | Vacuum zone table for stability | T-slot or partial vacuum |

| Spindle Configuration | Multiple/ATC spindles | Single spindle, some ATC |

| Production Scale | Large-scale, batch production | Small to mid-scale, decorative work |

| Ideal Use Case | Modular cabinet, wardrobe, shelf production | Artistic engraving, signage, prototype making |

A cnc nesting machine is built for full-board processing. It can:

Cut precise shapes from large MDF or plywood panels

Drill dowel or connector holes

Groove slots for cabinet backs or rails

Perform multiple cuts in one run using nesting optimization

Meanwhile, a wood cnc router is more about detail and depth. It can:

Engrave intricate designs and text

Carve 3D patterns and reliefs

Work on curved or cylindrical wood with rotary axes

Be adapted for mold-making and sign-making industries

Nesting machines lead the way in automation.

They usually feature:

Automatic loading arms or suction cups to handle large boards

Conveyor-based unloading tables for finished parts

Labeling systems that print part identifiers

Smart nesting software that reduces material waste

This streamlined workflow is perfect for a factory that needs to process dozens or hundreds of furniture pieces per day.

In contrast, a wood CNC router is more manual. You’ll need to:

Load materials manually

Change tools by hand unless using an ATC variant

Rely on the operator to manage files and layouts

| Material | CNC Nesting Machine | Wood CNC Router |

|---|---|---|

| MDF | ✅ | ✅ |

| Plywood | ✅ | ✅ |

| Solid Wood | ✅ | ✅ |

| Acrylic | ❌ | ✅ |

| Soft Metals (Aluminum) | ❌ | ✅ |

| PVC/Plastic Board | ✅ | ✅ |

| Foam/Foam Board | ❌ | ✅ |

While both machines support various wood-based materials, the wood cnc router supports a broader spectrum — including acrylic, foam, and soft metals, making it ideal for sign makers, prototype designers, and craftspeople.

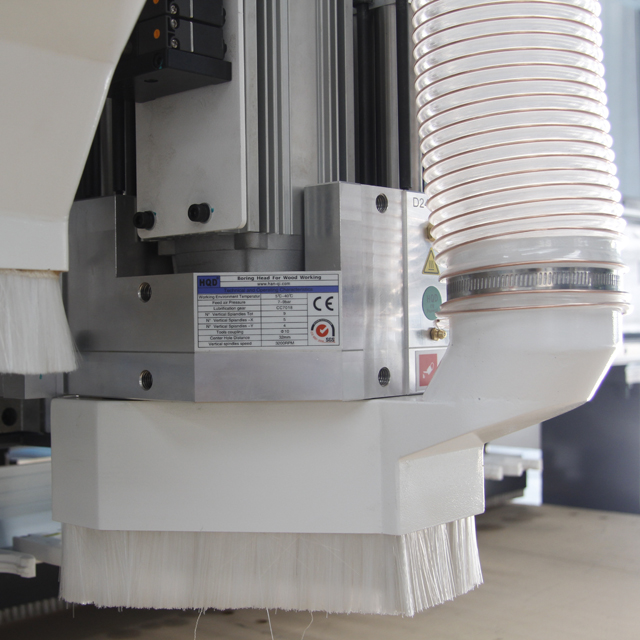

Nesting CNC machines typically feature:

A heavier bed structure to withstand continuous high-speed cutting

Dual Z-axes or multiple tool spindles

High power ATC spindles (up to 12kW)

Enhanced dust collection and vacuum systems

Whereas wood routers often use:

A lighter frame

Single spindle

Lower-power motors (around 3–6kW)

Basic dust collection

This difference makes nesting machines much more suitable for long-term, high-volume production.

The cnc nesting machine thrives in a digital environment:

Works with nesting optimization software

Supports ERP/MES integration

Allows batch order import/export

Enables dynamic label generation

This is essential for smart furniture factories or smart production lines. You can feed in orders directly and get cut plans, tool paths, and labels auto-generated.

Wood CNC routers, on the other hand, usually use:

ArtCAM, Aspire, Ucancam for design

Basic tool path software without layout optimization

Limited connectivity to large-scale systems

A cnc nesting machine is designed for:

Continuous high-speed operation

Heavy-duty cycles

Durability over years of use

It features reinforced linear guides, dustproof mechanisms, and stable gantry movement, reducing wear and maintenance frequency.

Wood routers, especially low-end models, may experience:

Frame deformation over time

Reduced precision after prolonged operation

Frequent manual tool and material adjustments

Run a cabinet, wardrobe, or modular furniture factory

Require batch panel processing

Want optimized cutting layouts

Need automated material handling

Aim for just-in-time furniture production

Work with custom signs, gifts, or carvings

Need to engrave 2D/3D artwork

Operate a small workshop or prototyping lab

Want to carve non-wood materials like acrylic, aluminum, or foam

Have limited space or budget

Cabinet Manufacturers: Nesting software plans efficient cuts across entire panels, saving material costs.

Flat-pack Furniture Producers: Drill, groove, and cut panels in one cycle.

Smart Woodworking Factories: Connect machines to centralized order management systems.

These setups help save time, reduce waste, and lower dependency on skilled labor.

The shift toward Industry 4.0 means machines like the cnc nesting machine are becoming a staple in automated workshops.

Features like:

Cloud-based nesting

Online order-to-machine systems

Integrated labeling and barcoding

...allow seamless production flow from customer request to final delivery — something traditional CNC routers are not built for.

With so many options on the market, choosing a reliable machine provider is crucial.

DWD offers:

Robust cnc nesting machines designed for longevity

High-speed ATC routers

Friendly control systems even for beginners

One-stop service with installation, training, and tech support

Whether you're upgrading an old system or building a smart factory from scratch, DWD provides dependable, efficient machines to grow your business.

Choosing between a wood cnc router and a cnc nesting machine depends entirely on your business goals.

If you need versatility and creative freedom, a wood router fits well.

But if you aim for streamlined, high-output panel furniture production, the cnc nesting machine is the future-ready choice.

DWD’s cnc nesting machine lineup offers the speed, accuracy, and integration you need to stay ahead.

A: It mainly handles wood-based panels like MDF, particle board, plywood, and melamine boards. It's built for high-speed, large-scale cuts with optimal precision.

A: Yes, simple grooves and patterns can be engraved, but for intricate or deep 3D engraving, a wood cnc router is more suitable.

A: Most systems are user-friendly and come with software-based automation. Basic training is usually sufficient for skilled operators to get started quickly.

A: Absolutely. Many small furniture manufacturers begin with a wood router and transition to nesting systems as production scales.

A: Yes. DWD offers full technical support, including machine setup, software configuration, and troubleshooting to ensure smooth operation from day one.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com