close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

Thinking about investing in a CNC router? You’re not alone. Cabinet makers, furniture manufacturers, and modern workshop owners are increasingly embracing automation to meet production goals and customization demands. But buying a cabinet making cnc router isn’t like picking a power tool off the shelf.

Did you know that improper machine selection is one of the top causes of production delays in cabinet shops? With so many features and configurations available, it’s easy to feel overwhelmed.

In this article, we’ll walk you through everything you need to consider before buying a cabinet making cnc router. From workspace logistics to control systems, we’ve got you covered.

Not all cabinet making cnc router machines are suitable for every material. Think beyond wood:

Plywood: Requires solid clamping and vacuum hold.

MDF: Demands precise cutting with minimal chipping.

PVC and plastics: Need slower spindle speeds and specialized bits.

Use this quick reference:

| Material | Recommended Spindle Power | Vacuum Required |

|---|---|---|

| Plywood | 4.5kW and above | Yes |

| MDF | 3.0–4.5kW | Yes |

| Softwood | 2.2–3.0kW | Optional |

| Plastic/PVC | 2.2kW (with cooling) | Optional |

Ask yourself:

Are you producing custom cabinets or mass production batches?

Is automation important for tool changes?

Do you need a smart nesting system?

Choose a CNC router based on your actual shop workload. Overbuying can waste budget, while underbuying will hurt productivity.

Your cabinet making cnc router needs clearances not just for the bed size, but for material loading/unloading, dust collection, and operator safety.

Measure twice, install once:

Leave 3–5 feet around the machine for safe access.

Consider entry points: can full sheets be maneuvered easily?

Plan for a dust collection system nearby.

Confirm if your shop has three-phase or single-phase power.

Check voltage compatibility (commonly 220V or 380V).

Place routers in well-ventilated areas away from direct heat and moisture.

CNC routers vary by the number of axes:

3-axis: For basic panel cutting, drilling, and engraving.

4-axis: Adds rotation—ideal for edge profiling and shaping.

5-axis: High-precision work, mostly used for curved cabinets and 3D panels.

For most cabinet makers, a 3-axis cabinet making cnc router provides the best value-to-performance ratio.

Different bed types affect hold strength and flexibility:

| Bed Type | Best For | Note |

|---|---|---|

| T-slot | Prototyping and small jobs | Flexible but slower setups |

| Vacuum table | High-volume cabinet panels | Fast, strong hold |

| Hybrid (both) | Mixed-use shops | Combines speed and flexibility |

The spindle is your cutter’s heart:

Choose air-cooled spindles for easy maintenance.

Opt for water-cooled for long jobs and quieter performance.

Match power rating to material hardness and job length.

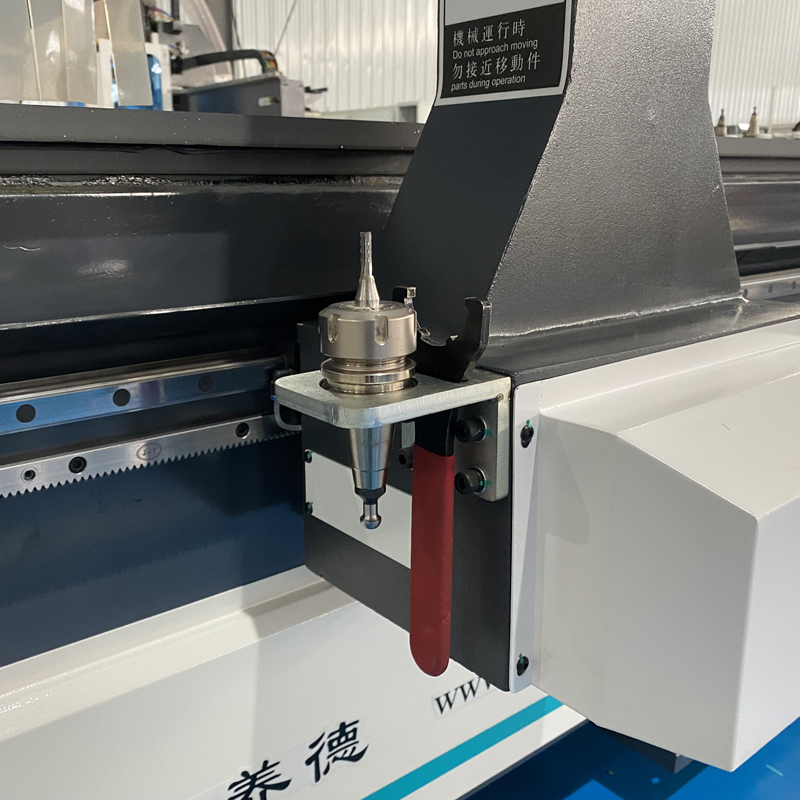

Manual tool change is okay for small batches. For production?

Go for ATC (Automatic Tool Changer) systems to reduce downtime.

Rack and pinion: Durable and great for long tables.

Ball screw: High precision for shorter axes.

Stepper motors: Budget-friendly, great for basic jobs.

Servo motors: For faster, more accurate cabinet making.

A cabinet making cnc router must support nesting and toolpath optimization. Key features to look for:

Automatic toolpath generation

Labeling and part tracking

Real-time preview and error checking

Look for compatibility with:

Cabinet-specific design tools

G-code output

3D visualization features

Avoid steep learning curves. Pick routers with:

Touchscreen interfaces

English-language support

Built-in simulation modes

Dust isn't just a mess—it’s a fire hazard and health risk. Your router must:

Support 2-port or 4-port dust collection adapters

Allow quick chip clearing during tool changes

Be connected to an external vacuum or cyclone unit

Add a table like this to visualize:

| Router Size | Dust Port Size | Suction Power Required |

|---|---|---|

| Small (<4'x4') | 2 inch | 1.5–2.0 HP |

| Medium (4'x8') | 4 inch | 3.0 HP |

| Large (>5'x10') | 6 inch | 5.0+ HP |

Safety is not optional. Your cabinet making cnc router should include:

Emergency stop buttons

Enclosed cutting area or safety shields

Automatic tool sensor or Z-height probe

Maintenance checklist:

Weekly lubrication of guide rails

Monthly vacuum system checks

Replace worn collets and belts regularly

Technology changes fast. Make sure your CNC router is:

Upgradeable: Add-on modules like auto labelers, drill blocks.

Remote compatible: Some systems allow cloud-based file loading.

Modular: Easier to replace spindle, controller, or motors individually.

Buying a cabinet making cnc router isn’t just about machine specs—it’s about aligning your production needs, workspace, and long-term goals. From power requirements to drive systems, from nesting software to safety protocols, each choice affects productivity.

DWD offers a professional range of high-performance cabinet making cnc router machines tailored for modern furniture manufacturing. Whether you're upgrading or starting out, DWD’s solutions are designed to meet your workshop's exact needs with durability, precision, and expert support.

A: Cabinet making cnc routers can handle MDF, plywood, softwood, PVC, plastics, and more, depending on the spindle and bit configuration.

A: Yes. Look for CAD/CAM programs that support nesting, part labeling, and auto toolpath generation tailored for cabinet layouts.

A: Absolutely. Desktop or compact 3-axis models are perfect for small workshops with limited space.

A: Most users get productive in a few days with intuitive interfaces. Formal training or tutorials accelerate learning.

A: Yes. DWD offers expert technical support, training resources, and guidance throughout installation and operation.

Copyright 2022 DWD MECHATRONICS CO.,LTD

Sitemap |Technology by leadong.com